The project SOLSTICE: materials and joining for energy storage

With the virtual kick-off meeting held from February 9 to 11, the four-year research project officially began, involving an international team composed of 9 research centers and universities and 3 industrial partners: Helmholtz-Zentrum Dresden-Rossendorf (Germany), Sintef AS (Norway), Eidgenössische Materialprüfungs- und Forschungsanstalt (Switzerland), Centro de Investigaciones Energéticas, Medioambientales y Tecnológicas - CIEMAT (Spain), Deutsches Zentrum für Luft- und Raumfahrt (Germany), Politecnico di Torino (Italy), Norges Teknisk-Naturvitenskapelige Universitet NTNU (Norway), Uninova - Instituto de Desenvolvimento de Novas Tecnologias - Associação (Portugal), Quantis (Switzerland), Sensichips Srl (Italy), Fzsonick SA (Switzerland), Imperial College of Science Technology and Medicine (UK).

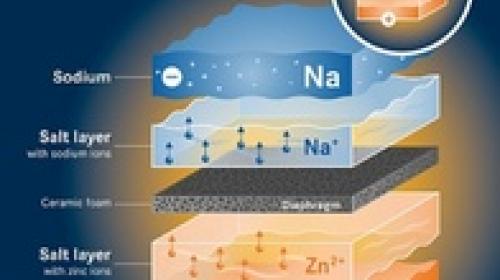

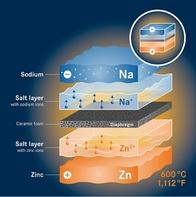

The Politecnico of Turin, with the participation of the GLANCE group (“Glass, glass-ceramics and composites”) from DISAT and the involvement of the Interdepartmental Center J-TECH@POLITO, coordinates the design and fabrication of joining materials based on glass-ceramics and brazing alloys for the production of hermetic connectors and sealing systems used in the two types of batteries. The ultimate goal of the SOLSTICE project (Sodium-Zinc molten salt batteries for low-cost stationary storage), funded under the Horizon 2020 program and coordinated by the Institute of Fluid Dynamics at Helmholtz-Zentrum Dresden-Rossendorf (HZDR) in Dresden, Germany, and SINTEF in Trondheim, Norway, is to develop two types of energy storage batteries based on molten zinc and sodium. Both battery concepts will be brought to TRL5 and validated by four demonstrators operating under real conditions by the end of the four-year project.

“The materials and joining technologies designed and developed in the SOLSTICE project,” explains Professor Federico Smeacetto from DISAT, the project’s principal investigator at Politecnico, “will be evaluated in terms of chemical and thermomechanical compatibility with the metallic and ceramic materials used to produce hermetic connectors operating in corrosive environments. Furthermore, new glass paste formulations will be developed with the aim of minimizing joining temperatures and battery costs by employing sinter-crystallization and deposition techniques aimed at improving the sealing process in terms of porosity and potential defects.”