The AMPS Project Advances Solid Oxide Technologies for the Energy Transition

More than 60 people—including industry experts, potential end-users, and stakeholders interested in emerging energy technologies—attended the international workshop “Unlocking the Potential of SOC Technologies for a Decarbonized Future” on May 30. The event was organized and promoted by the European project AMPS – Automated Mass Production of SOC Stacks, with Politecnico di Torino as a partner. The university’s contribution came through the research team formed by Marta Gandiglio, Massimo Santarelli, Paolo Marocco, and Alessandro Magnino from the “Galileo Ferraris” Energy Department (DENERG), and Giovanni Andrea Blengini and Isabella Bianco from the Department of Environment, Land and Infrastructure Engineering (DIATI).

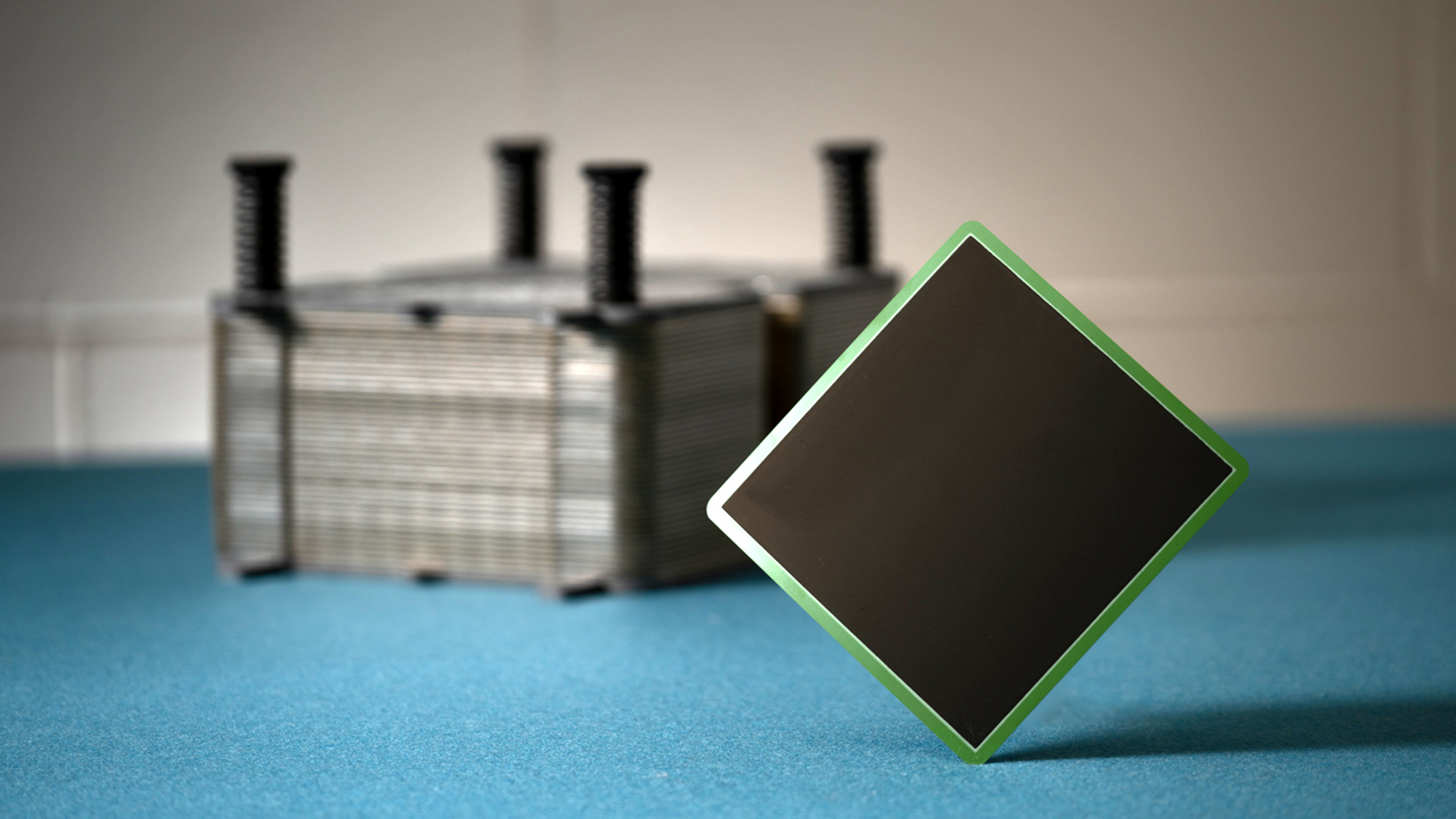

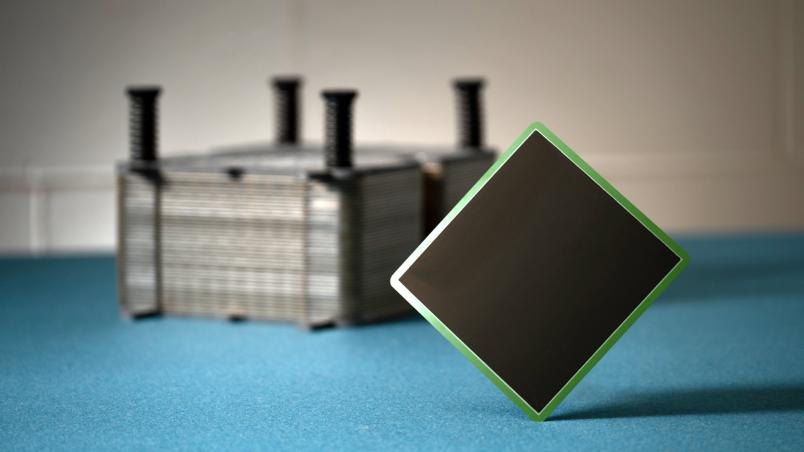

During the online event, major European players in the sector shared tangible results and industrial perspectives related to the development and dissemination of SOC (Solid Oxide Cells) technologies—high-temperature electrochemical devices considered strategic for the energy transition. Topics included the large-scale automated production of SOCs, showcased through AMPS project advances and the industrial experience of project partner Elcogen.

Several real-world applications of SOCs were presented: high-temperature electrolyzers (SOEC) for green ammonia production (project presented by Topsoe); low-emission steel production (HySteel project presented by LEAP); biogas-fueled SOFCs in agricultural plants, with end-users such as the Monviso Agroenergia Consortium; maritime applications for SOFC propulsion systems (NAUTILUS project presented by DLR).

PoliTO shared its integrated vision on market potential, future scenarios, and regulatory challenges, contributing to the creation of a realistic roadmap for the widespread adoption of SOC technologies in Europe.

Nearly two years since its launch, the AMPS project has achieved major milestones across the entire SOC production chain, demonstrating the feasibility of advanced automation and integrated digitalization. Among the key results we find 100% recycling of production process residues without compromising cell quality compared to reference samples; development and implementation of working prototypes for robotic system for automatic component handling (both cells and stacks) and a vision and AI-based inspection system capable of high-speed image defect classification; advancements in laser welding of interconnectors to meet Elcogen’s industrial specs, including the analysis of main defect types and optimized coating processes.

Progress has also been made on the digital twin of the production line, including mapping of the current cell production process and defining a tracking architecture for cell and stack components.

Validation is ongoing for an automated stack assembly station, which includes inline inspection technologies for detecting critical defects. Additionally, economic and environmental assessments comparing pre-AMPS and AMPS-derived layouts are being finalized, with tools developed for optimizing SOC roles in real-world scenarios.

These achievements support the project’s overarching goal: by 2027, to demonstrate automated and traceable production of SOC stacks at a cost below €800/kW for volumes of 100 MW/year, thus making the technology industrially competitive.

The workshop was a key moment to highlight the activities of AMPS (2023–2027), which aims to make SOC technologies more accessible, reliable, and cost-effective. Launched in 2023 with €6.6 million in funding from the Horizon Europe program, AMPS involves 11 partners across 6 countries. Its mission is to develop and test high-speed automated SOC production technologies; integrate intelligent AI and digital twin-based quality control systems; reduce production costs below 800 €/kWel (SOFC mode) at industrial scale; build a European value chain of machinery and skills for SOC system manufacturing.

All technologies and methods developed within AMPS will be tested and implemented at Elcogen’s new production facility—the project’s industrial proving ground.

Politecnico’s scientific role includes analyzing the economic and environmental impact of the new production lines, ensuring the target production cost lower than 800 €/kW is achieved. The team also develops optimization tools for the sizing and scheduling of SOC systems (SOFC, SOEC, rSOC) across various application scenarios. This analysis helps identify the use cases and boundary conditions (e.g., energy costs, regulatory context) that make SOC technologies economically and environmentally advantageous.

The research group has also published peer-reviewed studies on the techno-economic-environmental feasibility of SOC technologies, focusing on industrial scenarios: