Smart Technologies for Enhanced Industrial Water Management

Developing intelligent technologies for water treatment with the goal of combining water conservation, recovery of precious metals and energy production within a single integrated process. Additionally, the aim is to enhance the environmental and economic sustainability of industrial sectors with high water and energy demands. These goals have been successfully pursued by Politecnico di Torino through its participation in the European project intelWATT (intelligent Water Treatment Technologies for water preservation combined with simultaneous energy production and material recovery in energy intensive industries).

Sensor Technology for Online Water Monitoring

Electroplating processes, commonly used to manufacture metal objects by depositing metal onto specific moulds, have long generated wastewater rich in heavy metals, posing significant environmental and human health concerns. To address this issue, Politecnico has developed a real-time monitoring system for trivalent chromium, a metal widely used in electroplating. Although it is less toxic than its hexavalent form, trivalent chromium is still subject to strict environmental regulations, particularly regarding freshwater, where allowable concentration limits are extremely low.

Traditionally, the detection of these pollutants relies on complex, time-consuming laboratory analyses, which are not always compatible with the pace of industrial production. However, the University has developed an optoelectronic system that can be easily integrated into production lines and is capable of delivering accurate and real-time chemical monitoring. This area of research was led by Giulia Mossotti, Research Assistant at Chilab-ITEM, the laboratory of the Department of Applied Science and Technology-DISAT, based in Chivasso. “It was highly interdisciplinary work,” says Sergio Ferrero, Full Professor at DISAT and her supervisor. As coordinator of the activities related to the sensors, Ferrero adds: “In addition to analytical chemistry, the project involved expertise in electronics, mechanics, optics and computer science to design an integrated system capable not only of measuring, but also of interpreting and transmitting data in real time”.

The process was developed in close cooperation with companies involved in the management of process water containing heavy metals, and a pilot demonstrator was implemented in Germany at the facilities of BIA GmbH, a company specialising in electroplating. “This approach made it possible not only to validate the technology in a real-world setting, but also to tailor it to the operational needs of industrial plants, ensuring reproducible results and stable performance over time”, Professor Ferrero points out.

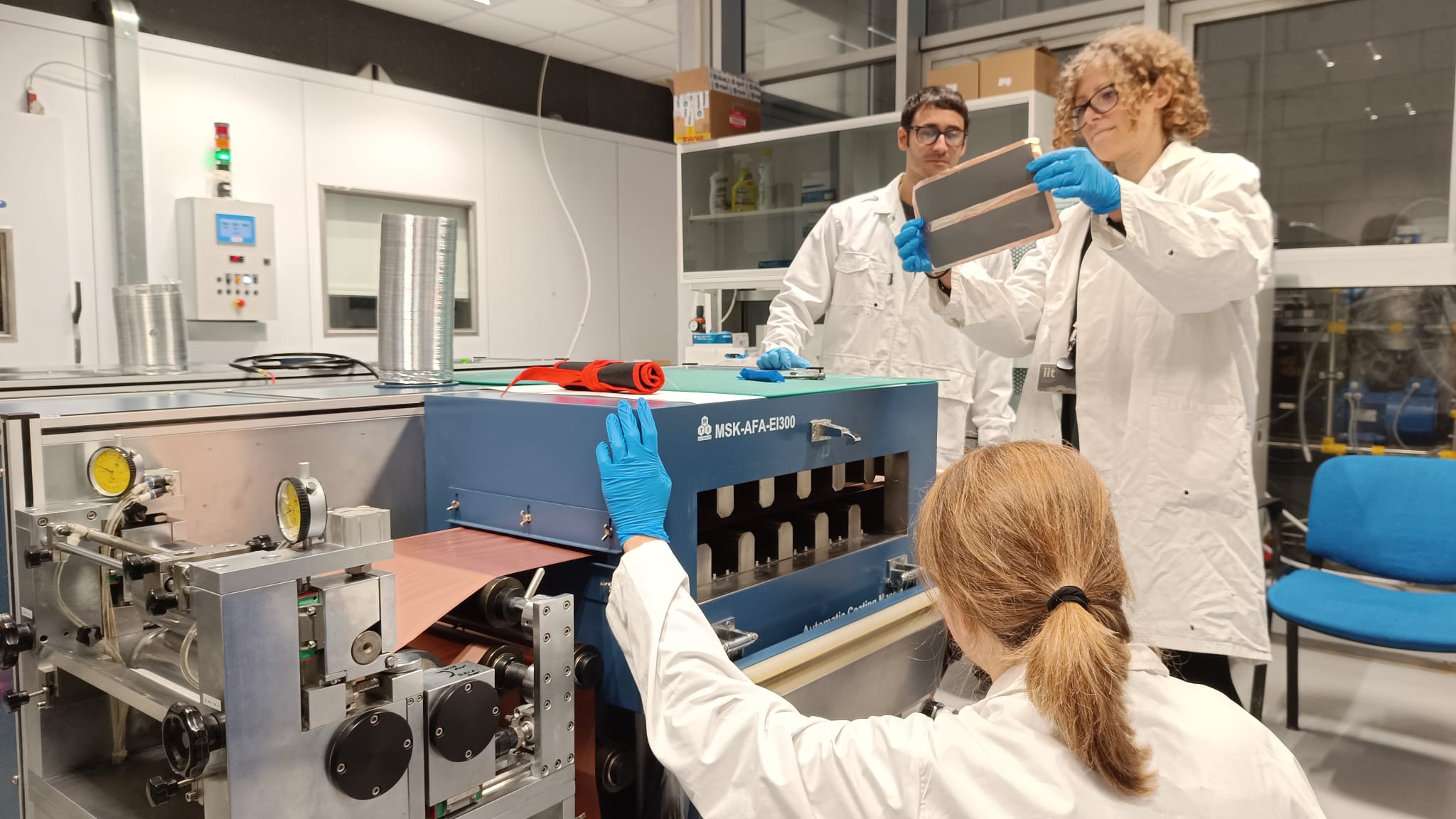

Graphene Oxide-Based Membranes

Another key focus of the project was water filtration membranes, tools that can also offer additional functionalities, although these are often achieved using toxic materials or involve unsustainable manufacturing processes. The goal of intelWATT was to develop filtration technologies free of fluorinated compounds and polymers.

Andrea Lamberti, Full Professor at DISAT, explains: “The solution we identified involves graphene-based membranes, a material with properties well-suited for these applications. It does not require polymers or fluorinated compounds and can be stacked in ultra-thin layers configured in different ways depending on the specific type of filtration required”.

The focus was specifically on graphene oxide, a chemically modified form that disperses in water, is biocompatible, and provides a surface resistant to bacterial adhesion (anti-fouling), all of which are ideal characteristics for the filtration of wastewater or other types of industrial water.

But the project did not stop there: one of the potential applications of graphene oxide membranes also involves energy production. “We successfully tested graphene oxide membranes, which are less expensive than conventional ones, applied to reverse electrodialysis (RED) technology – explains Lamberti – This technique allows to recover energy by mixing waters with different salinity levels: for example, high-salinity wastewater with lower-salinity water”.

Another application already tested involves the recovery of lithium from aqueous solutions. “This is a highly promising application for battery recycling and highlights the potential of graphene oxide in this field as well”, notes Luisa Baudino, Research Assistant at DISAT and a member of the project team.

“More broadly – adds Professor Lamberti – the importance of graphene-based membranes lies in their strong potential for technology transfer and their readiness for industrial-scale application, which is now ready for deployment”.