AMPS project powers the Future of decarbonization

Electrification stands as the primary choice for decarbonisation efforts, yet its application is not always technically viable or cost-effective. Industries facing significant decarbonization challenges, such as hard-to-abate sectors (e.g. steel, cement, fertilizer) as well as heavy-duty transport (e.g. trucks, maritime, aviation) require alternative solutions. Hydrogen or hydrogen-derived fuels (commonly known as e-fuels) emerge as crucial elements for transitioning away from fossil fuels in this demanding context.

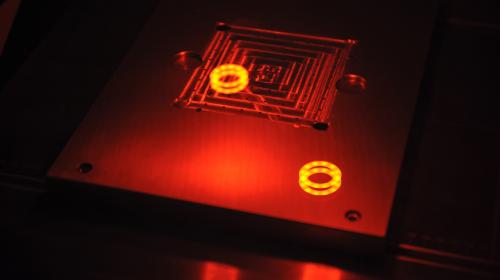

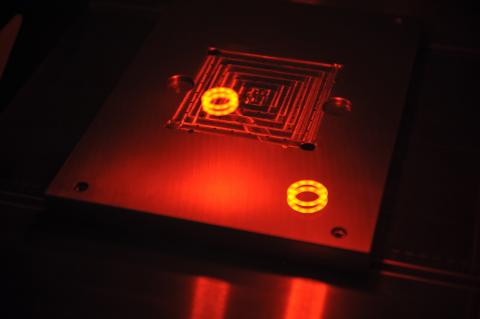

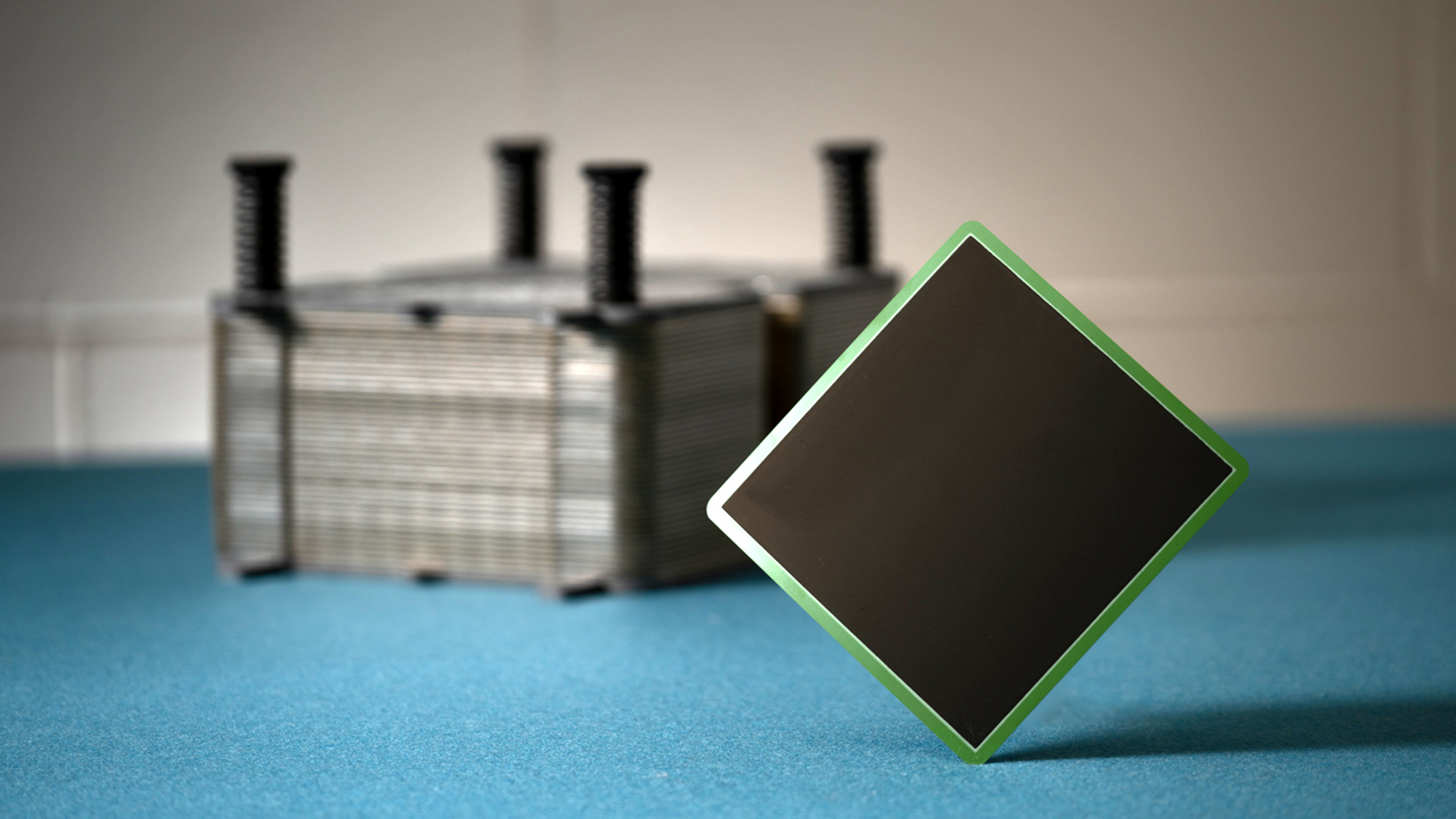

To successfully navigate this transition, efficient and affordable electrochemical technologies (fuel cells and electrolysers), becomes imperative. Notably, high-temperature technologies offer best-in-class efficiencies and extensive flexibility in handling various input streams. Moreover, they demonstrate the unique capability of working in reversible mode within the same component, enhancing their overall versatility and utility in diverse applications.

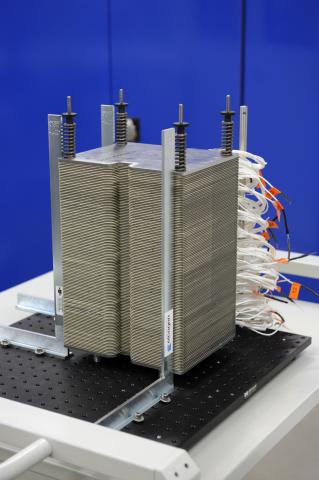

AMPS is a Horizon Europe funded project (8.7 M€ budget, 6.6 M€ funding) started in June 2023. The primary focus of this project is the advancement, demonstration, and validation of cost-effective, high-volume production techniques and quality control measures for manufacturing SOC (Solid Oxide Cell) components and stacks. These goals are achieved within real-time production environments, underscoring the project's commitment to practical and impactful contributions to the field.

The primary objectives of AMPS include automated high-speed production of SOC cells, bipolar and interconnect plates, along with automated high-speed stack assembly, with integrated quality control. A complete component tracking and optimized mass-manufacturing will be achieved by using virtual twins. Ultimately, the project aims to assess and demonstrate a target stack manufacturing cost of <800 €/kW at production volume of 100 MW/year, with the all-embracing objective of establishing a dedicated European supply chain for SOC manufacturing equipment.

In the framework of the AMPS project, Politecnico di Torino is responsible for evaluating the cost-effectiveness of the AMPS production process in comparison to conventional Solid Oxide Cell (SOC) production methods, thanks to the commitment of the working team led by Marta Gandiglio, which involves also Massimo Santarelli, Paolo Marocco and Alessandro Magnino from DENERG department and Giovanni Andrea Blengini and Isabella Bianco from DIATI Department.

The analysis also includes a thorough life cycle assessment of the AMPS process to prove its environmental sustainability, with a particular focus on waste disposal and recycling to achieve a high level of circularity. A comprehensive overview of the manufacturing process, encompassing safety and regulation assessments, will be also provided.

Based on the results of the innovative AMPS manufacturing process, the ultimate goal is to disclose the role of SOC systems in promoting decarbonization across different end-use sectors in Europe. To this end, PoliTO will develop an ad-hoc optimisation tool to underscore the conditions that position SOC systems as the optimal solution for industrial and transport applications. Lastly, PoliTO will lead efforts in dissemination, communication, and exploitation activities.

This initiative unites prominent European companies engaged in the production chain of Solid Oxide Fuel Cells and Solid Oxide Electrolysers. The project is coordinated by VTT and comprises automation firms such as Rocksoft and Smartal, along with manufacturing equipment producers SITEC, Haikutech, and Dosetec. The project also involves cell manufacturing by Elcogen AS and stack manufacturing by Elcogen Oy. These industry partners receive support from research institutes PoliTO and VUTS.