Towards More Efficient and Infrastructure-Compatible Green Hydrogen Production

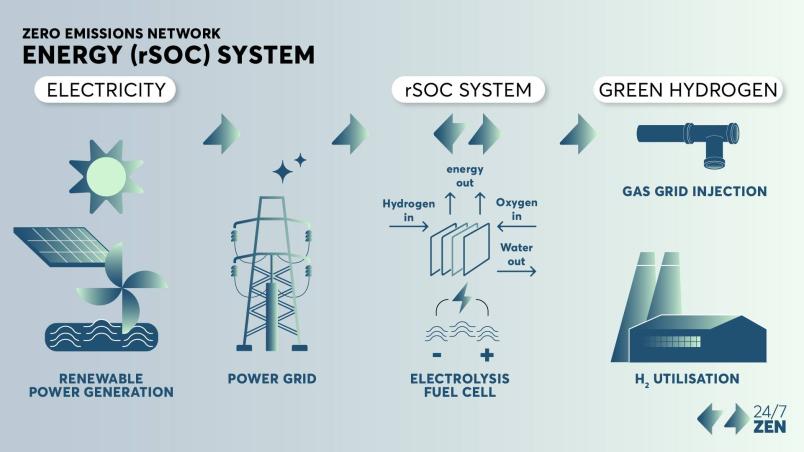

The project aims to create an innovative energy conversion system based on solid oxide cell technology and to demonstrate its compatibility with both electricity and natural gas networks. Compact and transportable, the plant can be easily installed where needed. Coordinated by the Institut de Recerca en Energia de Catalunya (IREC) in Barcelona, 24_7 ZEN is funded by the European Union (Clean Hydrogen Partnership) with €5.5 million and by the Swiss State Secretariat for Education, Research and Innovation (SEFRI) with an additional €2.2 million, for a total duration of 36 months.

The Clean Hydrogen Partnership is a public-private initiative supported by the Horizon Europe programme. It funds research and innovation activities to accelerate the development of clean and sustainable hydrogen technologies, and Politecnico di Torino is one of its members.

Federico Smeacetto, professor at the Department of Applied Science and Technology-DISAT and principal investigator for Politecnico, explains: “We helped develop a reversible energy conversion system that can either transform chemical energy into electricity or use electricity and steam to produce hydrogen and oxygen”.

The system fits within a standard container, making it easy to transport and install wherever needed. The prototype will be tested at the Centre for Research and Technology Hellas (CERTH) in Thessaloniki, Greece, one of the project’s 14 international partners.

The research focuses on three main aspects: component innovation, essential for improving durability and efficiency; system integration, first within the container and later into the grid; and multidisciplinary collaboration, leveraging the complementary expertise of public and private partners.

A key role is played by SolydEra, a company specialised in solid oxide cell technology, which works alongside Politecnico to improve the device’s efficiency. The university contributes its expertise in metallic material coating techniques used in the solid oxide cell stack.

Professor Smeacetto explains: “To protect the different materials operating at around 750 °C, we have developed a special ceramic coating for the metallic components of the solid oxide cells”. The coating is applied through electrophoretic deposition, a fast and precise method that uses an electric field to evenly distribute ceramic particles onto component surfaces. Once deposited, the particles are consolidated through an innovative thermal sintering process, producing a compact and durable layer. “This process allows us to obtain in just a few minutes a coating that would normally take hours with traditional methods, improving both the system’s efficiency and lifespan”, adds Professor Smeacetto. The technology, developed within 24_7 ZEN and recognised by the European Commission’s Innovation Radar, is now ready to be transferred to industry.

The project is still underway. Its ultimate goal is to develop and validate a scalable and replicable system, adaptable to multi-megawatt plants and to enable the cost-competitive production of renewable hydrogen, bringing Europe closer to climate neutrality and energy independence.